Products

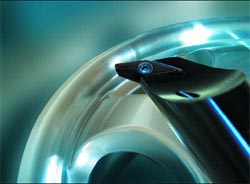

LMT-Fette is pleased to announce the introduction of

a new diamond film coating, ALUTEC

LC600A. This new grade features a tungsten carbide substrate

engineered for toughness

and wear resistance, and a PCD diamond film hard coating

up to 10,000 Hardness Vickers.

The new product will revolutionize rough and finish turning

applications. LMT-Fette is pleased to announce the introduction of

a new diamond film coating, ALUTEC

LC600A. This new grade features a tungsten carbide substrate

engineered for toughness

and wear resistance, and a PCD diamond film hard coating

up to 10,000 Hardness Vickers.

The new product will revolutionize rough and finish turning

applications.

Application Area

With an excellent balance of carbide substrate toughness,

and highly wear resistant diamond

coating, LC600A is excellent for turning of cast aluminum

alloys. LC600A combined

with our BAL (Boehlerit Aluminum) geometry provides optimum

chip control and tool life in

aluminum alloys with either low or high silicon content.

The new PCD diamond-coating technology

of LC600A makes it possible to run at slower sfm ranges

from 650 to extremely high

ranges over 9,800, providing the wide range of sfm needed

when machining automotive

products such as cast aluminum wheels.

Materials

As stated above, LC600A’s primary application use

is in machining of cast aluminum automotive

products. Its performance is unmatched by the PCD coating

technology. The nano

crystalline and microcrystalline layering process in

LC600A inserts provides an excellent

hard coat surface needed for tool life and improved finishes.

Boehlerit offers the BAL

chip breaker geometry in ISO style inserts more cutting

edges than conventional brazed

tipped cutting edge inserts.

Advantages

Combining the toughness of tungsten carbide and the wear

resistance of PCD, LMT-Fette’s

LC600A insert grade is a new generation of diamond film

coating produced to compete

with conventional brazed PCD tipped inserts for machining

of aluminum alloys. This new

product offers five to ten times the tool life achieved

by conventional tungsten carbide

inserts. LMT-Fette offers its exclusive BAL geometry

designed specifically for short and long

chipping aluminum, materials providing optimum chip control

compared to brazed PCD flat

top style non-chip breaker inserts. |